3X MOTION Self-developed Servo AGV Transfer Trolley Design Case

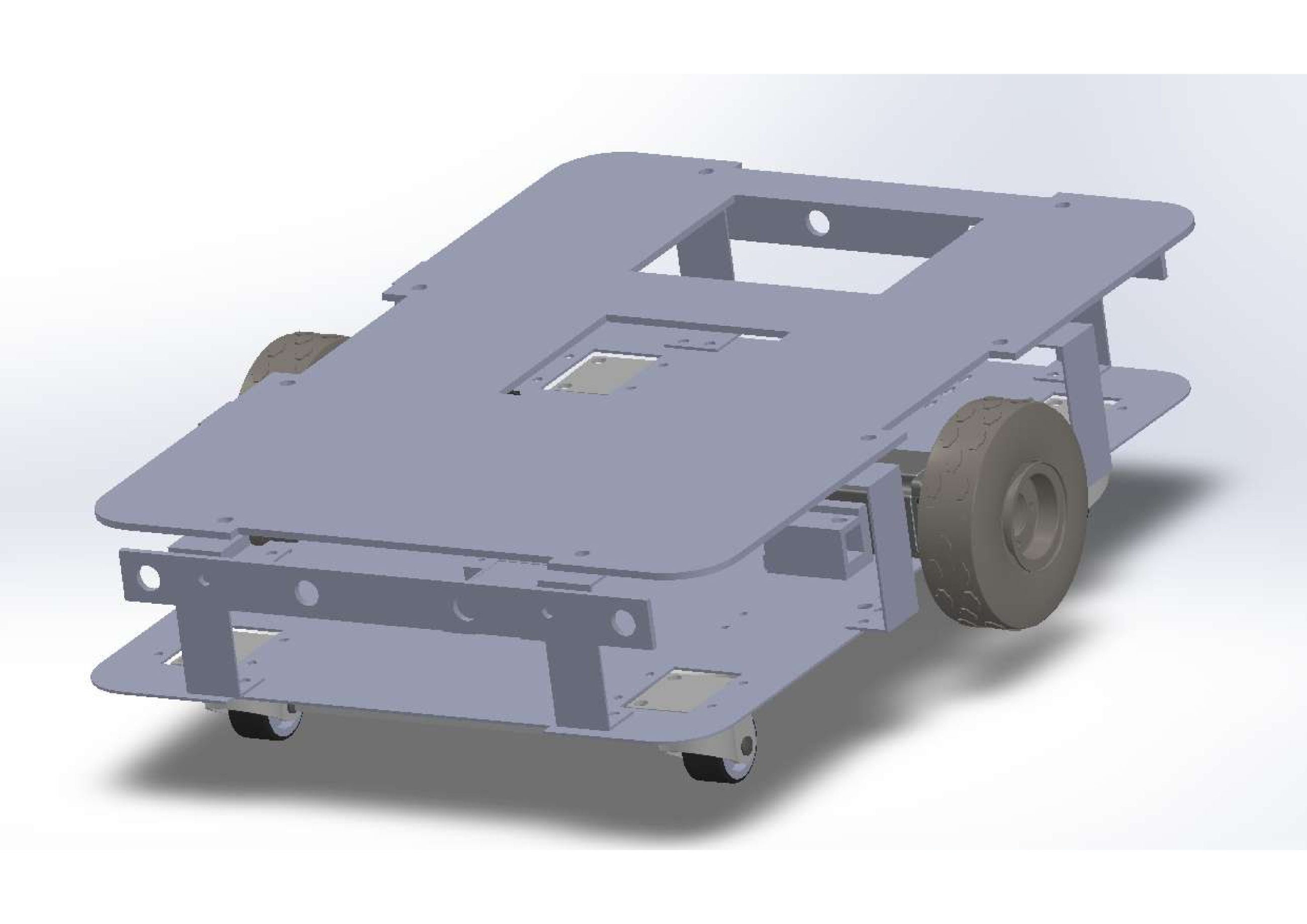

Chassis and Drive System

The AGV chassis adopts a differential drive layout and is equipped with a high-performance servo motor with a rated power of 400 W and rated voltage of 48 VDC. This motor has a 10-pole structure, a rated speed of 3000 rpm, and a maximum speed of 4000 rpm. It has a rated torque of 1.27 N·m and a maximum torque of 3.81 N·m. Coupled with a precision reducer with a reduction ratio of 10:1 and 152 mm diameter wheel set, it can output more than 30 N·m of wheel-end torque, providing stable and sensitive driving force for the entire vehicle.

The motor's torque coefficient of 0.127 N·m/A and back EMF coefficient of 8.6 V/Krpm ensure high response control and excellent speed stability. With a rated current of 10 A and a maximum instantaneous current of 31 A, it supports short-term high-load start-up capabilities. The motor features a low-resistance (0.28 Ω) and low-inductance (0.55 mH) winding design, effectively reducing heat generation and electromagnetic interference, ensuring long-term operational stability. The center of gravity is rationally distributed, minimizing jitters during turns and enabling smooth operation on both epoxy floors and tile floors.

You can see the product vedio here : https://youtube.com/shorts/rAJQpGtGNBo?feature=share

Power System and Battery Life Design

The power system uses a 24 V, 10 Ah lithium battery pack, managed by a BMS power management module for cell balancing, over-voltage and over-current protection, and temperature control. It supports both fast charging and offline charging modes.

Under a rated load of 10 kg and an average speed of 0.24 m/s, the overall system power consumption is approximately 34.3 W, and a single charge can last for more than 6 hours, meeting the material transportation needs of non-specialized industries.

Perception and Control Architecture

The AGV's control system is centered around motor performance demonstration, using an MCU-based control platform that divides the system into five functional modules: perception, positioning, planning, execution, and scheduling interfaces. Lower-level devices communicate and synchronize control in real-time via CAN and RS-485 buses, while the upper-level system manages task dispatching, status monitoring, and log management through the MQTT protocol, forming a complete motor performance monitoring loop. Ultrasonic sensors are used for obstacle detection, and interfaces for lidar and visual modules are reserved to support subsequent algorithm demonstrations and multi-sensor fusion control.

System Expansion and Application Prospects

The overall dimensions of the AGV chassis are 600 × 480 × 160 mm, with a weight of approximately 13 kg. The system reserves DI/DO, serial port, and expansion power interfaces, supporting OTA remote upgrades, operation log tracking, and abnormal data collection.

This AGV chassis will be exhibited at the SPS exhibition in Nuremberg, Germany in November 2025. The stand No. is Hall 3 - 240.